There are two main types of printing.

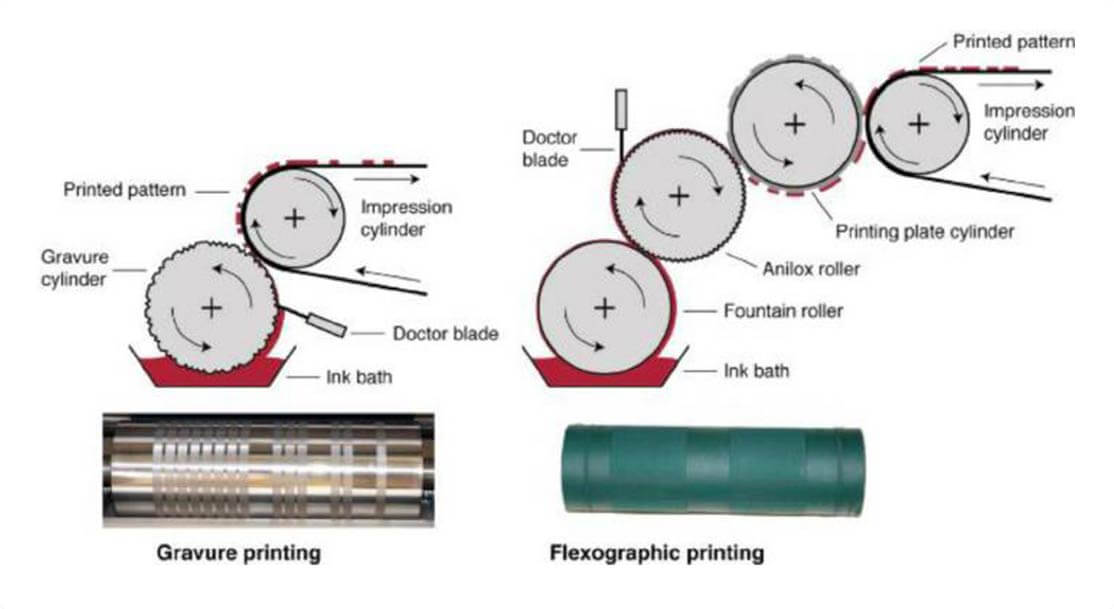

We use two main types of pouch printing: Flexographic printing and Rotogravure printing. Digital printing is also available and at small MOQs.

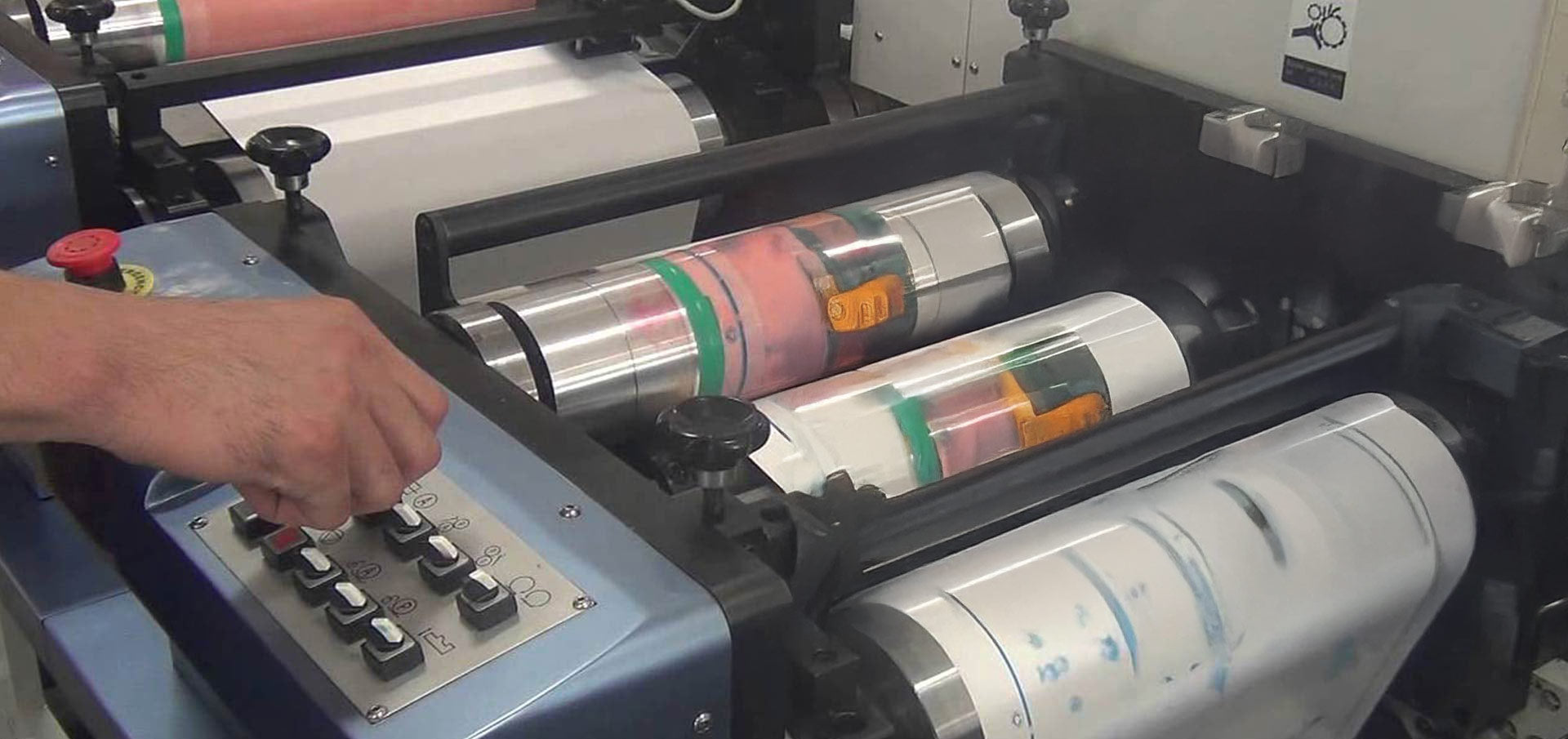

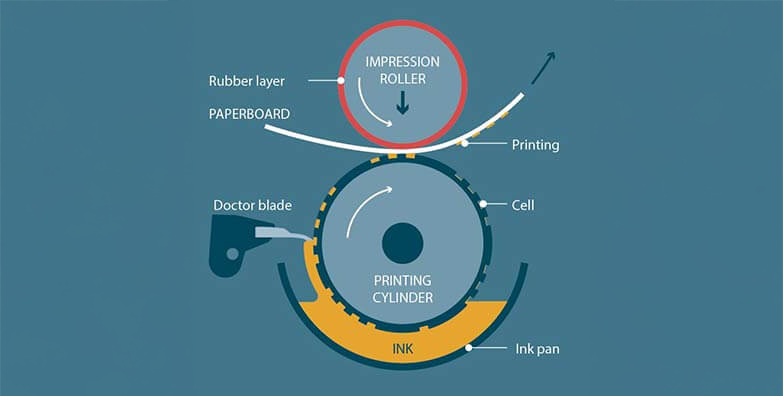

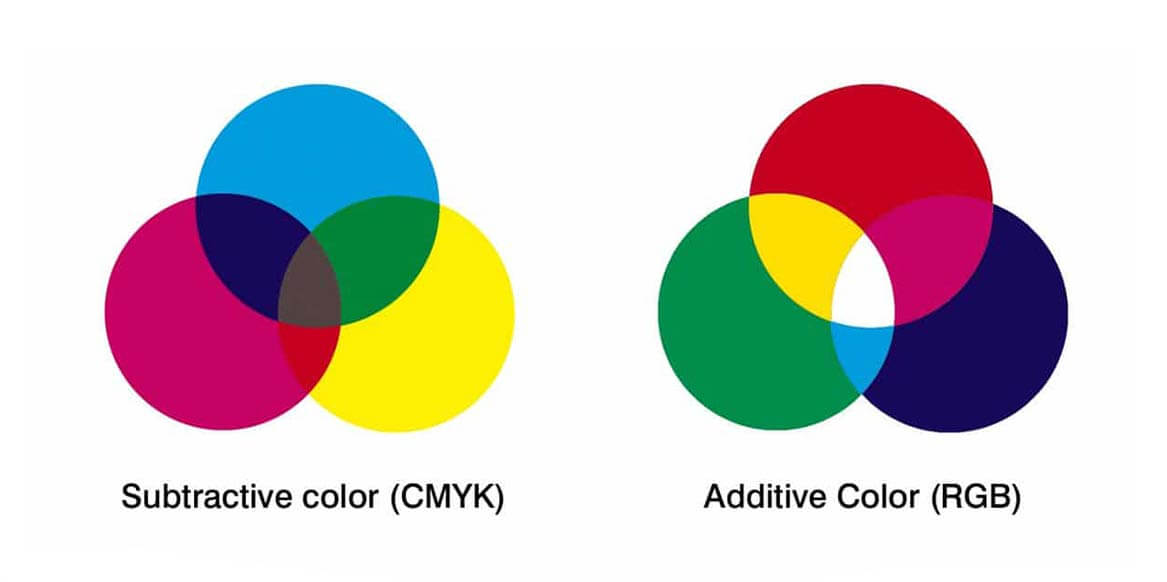

If you need Flexographic printing, you need to understand this is the type where roll stocks are fed into a press. In a Flexo printing machine, there are different parts or a series of printing units. As the roll passes over each printing unit, a single color among the CMYK (Cyan, Magenta, Yellow and Key) colors gets printed.

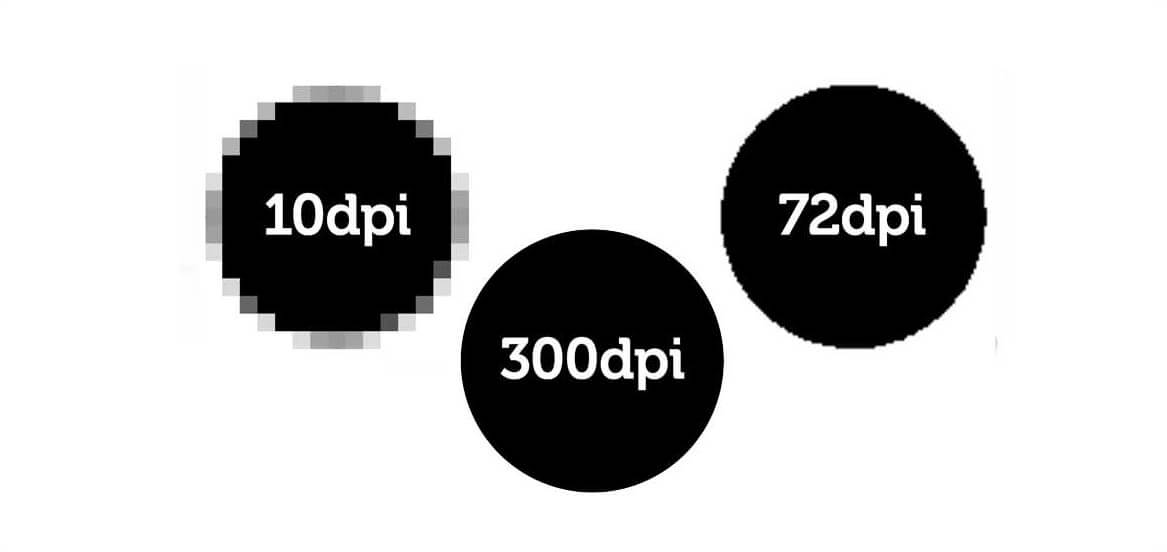

Each printing part has its specific function and advantage all of which contribute to the quality of the final print quality. Typically, Flexo printing produces a lower printing quality than the rotogravure printing designs.

But technological advances over the past few months have given Flexo printing a significantly improved print quality.